Manufacturing ERP System

The modern ERP system based on chain ideology with Gantt production view and hierarchical structure. Fully integrated with all modules for manufacturing.

Click here for a guided demo tour

Ready out of the box

No extra costs

Modular structure

Chain workflows

All modules included

Complete processes

Good documentation

Integrated user guide

Why choose Binu ERP System

In today’s manufacturing market, the need for a robust and agile Enterprise Resource Planning (ERP) system has never been more critical. Binu ERP is a manufacturing software that simplifies complex manufacturing. With intuitive design that reduces the learning curve and ensures that users at all levels can easily navigate the system. With it’s modular structure and smart features the software enhances operational efficiency, resource management, and overall productivity across the board or departments. Binu ERP is a intuitive tool for manufacturers looking to improve quality and optimize their production by data-driven decision making and future growth.

All in one package

Easy implementation

Custom options

Free software updates

Simple support included

Enterprise security

No extra consultancy

No extra development

No extra support fee

No extra suprices

%

Average reduction of operational costs

%

Average reduction of paper based work

%

Average company efficiency increase

Based on avrage industry standards with ERP system adoption

Software for Manufacturing

One of the standout features of Binu ERP is its ability to seamlessly integrate and manage resources across the manufacturing spectrum. From raw material procurement to final product delivery, the system ensures that every component is tracked and optimized. This level of integration minimizes waste, reduces downtime, and ensures that resources are utilized to their fullest potential.

Perfect for discrete manufacturing processes

Products, parts and innovative components

Any type of production with assembly

Any type of Production

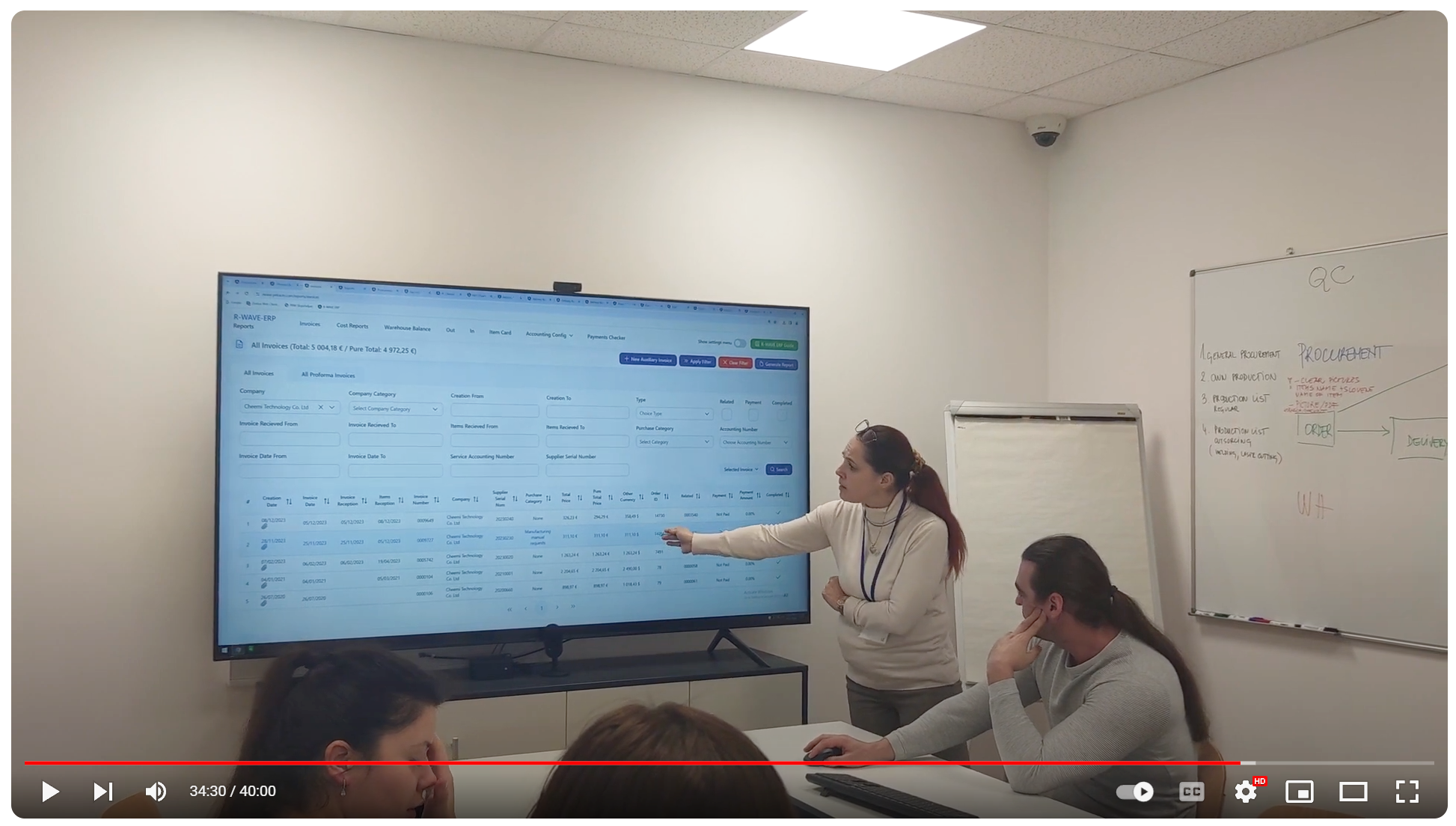

Manufacturing often involves complex processes that require precise coordination and timing. Binu ERP excels in streamlining these processes by providing real-time data and analytics. This enables manufacturers to make informed decisions quickly, adjusting production schedules and resource allocations on the fly to meet changing demands and mitigate any potential disruptions.

From the top floor down to the production floor level

Easy implementation and adoption for companies

Complete business flow with ERP

For Managers and Workers

Management needs can vary widely depending on the size and type of operation. Binu ERP is designed with scalability and customization in mind, making it suitable for both small-scale manufacturers and medium industrial enterprises. Its modular architecture allows businesses to tailor the system to their specific needs, ensuring that they only pay for the features they use while having the flexibility to expand as their operations grow.

Increase company productivity and efficiency

One system for everyone and all devices

Improve over all company performance

Binu ERP Modules

All modules is included and is fully integrated. From sales to delivery.

Free Online Resources

Binu ERP System offers detailed documentation that covers every aspect of the system. This includes user manuals, setup guides, and step-by-step instructions for various modules and features. Whether you are a new user looking to get started or an experienced user seeking advanced tips, the comprehensive documentation serves as a effective resource.

For our users we have additional resources in the support portal.

Binu Testimonial

«With Binu ERP we managed to create a custom production flow for the innovative development of the Slopehelper. The autonomous robotic with advanced technology for agricultural fieldwork. With the help of Binu ERP System development team we made modern ways of production more practical for everyone and time efficient compared to other systems we have tried.»

Read more about Binu for manufacturing of Special Purpose Vehicles (SPVs).

System Key Features

From management to workers

Possibility for customization

Fits any organisation structure

Interactive ERP documentation

Full reporting and statistics

Quality control and confirmations

QR code support for warehouse

Gantt chart for manufacturing

Marketing, sales and delivery

Chain ideology with hierarchy

Multiple warehouses support

Automatisations and self learning

Tools and equipment inventory

Procurement and outsourcing

Assembly, cost and tracking

Your Benefits

Save Business Hours

Improve workflows and get extra work hours and peace of mind for other tasks.

Improve Efficiency

Optimise production, quality and collaberation between departments.

Cloud Control

Amplify decision making with real time data and information from the cloud.

Logical Structure

Business processes by chain events and hierarchy methodology.

Increase Turnover

Track, analyse and add more value to reduce internal business gaps.

Simplify Operations

Refine business operations with smart features and faster production.

Replace manual processes and multiple programs with Binu ERP System.

Binu ERP pricing Plan

+ 6 Training sessions

3 Guided Training Sessions, before implementation

Understand your business: process discovery, ERP readiness assessment, walkthrough of Binu funcitonalities based on your case study, system review, Q&A

3 Training Sessions after the implementation

Department-specific workshops or advanced topics

📞 Support Plans

BASIC

- 12h response time

- Email, Phone, Chat

PRO SUPPORT

- 8h response time

- Email, Phone, Chat, Video call

ENTERPRISE SLA

- <4h response time

- Email, Phone, Chat, Video call, Dedicated Manager

⚙️ Optional Add-ons (One-Time Services)

ONBOARDING CONSULTATION

- A focused one-time session designed to help your team understand the system’s structure and workflows.

EXTRA TRAINING BLOCKS

- Department-specific workshops or advanced topics.

⚙️ Implementation Services (One-Time Fee)

Business process setup

- Help with implementation of business flow

Data Migration setup

- Import products, clients, suppliers, etc.

Accounting Setup

- Accounting and tax configuration (local requirements)

Other Services

- Specific requirements

Updates, News and Articles

Why Real-Time Data Matters in ERP: Better Insights, Better Outcomes

1. Introduction2. Why Data Quality is the Heart of ERP3. The Risks of Poor or Disconnected Data4. Real-Time Data and Advanced Reporting in ERP5. Practical Examples of Data in Action6. Disconnected Data vs. Connected Data in ERP7. Conclusion8. Frequently Asked Questions (FAQ) 1. Introduction In...

Full Operational Visibility Across ERP: Best Practices for Managing Connected Operations

Why Management Should Care About full Operational VisibilityBest Practices for Managing Connected OperationsStart with a Strategic VisionScalable Technology: Choose Systems That Grow with Your BusinessChange Management: Prepare Your Team for TransformationLeverage Product Structure and BOM as...

Why Disconnected Systems Kill Productivity in Modern Manufacturing?

Table of ContentsWhy Disconnected Systems Kill Productivity in Modern Manufacturing?The Hidden Cost of Disconnected ToolReal-Life Consequences of Fragmented SystemsIntegrated ERP: The Backbone of Modern ManufacturingKey Benefits of a Fully Integrated ERP System:Comparing Disconnected vs....

Frequent Asked Questions

How is Binu implemented for new companies?

Binu ERP can be implemented in many different ways, depending on factors like type of manufacturing, size and complexity. We have made lists of the most common ways to implement here.

What are the cancellation policy by terms?

The yearly recurring terms including a resignation period before the agreement renews. That means there is noe huge commitments or high risk to try the Binu ERP System for at least one year. Just notify us before the agreement renews that is stated in the terms of conditions so we we can prosess of resignation before the new period starts.

Will there be extra modules in the future?

Yes, we are constantly trying to adapt to our users needs and the market needs, that means we are always on the lookout for new improvments that would help our users with their business operations. Also with feedback from our users.

What are the risks of implementing?

Worst case scenario is hard to say for all potensial companies but one yearly subscription cost could be considered a low risk scenario. We do not force our clients into long contracts or huge commitments. We belive that it’s our product that drives growth for both parties.

Start With ERP System Checklist

The Start With ERP System Checklist provides a simple guide for small companies ready to begin their ERP journey. This checklist walks through essential steps, from assessing business needs and defining key requirements, to evaluating software options and setting a realistic budget. It ensures businesses are equipped to select the right ERP solution, prepare for a smooth implementation, and achieve long-term success.