Table of Contents

Introduction

ERP Business Process Mapping is a critical step in preparing any manufacturing company for a successful ERP implementation. Before selecting or going live with a system, manufacturers must fully understand how their operations work—from inventory to production. In this case study, we explore how a real-world company used process mapping to streamline its ERP deployment and improve cross-departmental efficiency.

What is Business Workflow Mapping?

Business workflow mapping is the process of visually documenting how tasks, decisions, data, and people interact within a company. It is a method for breaking down operational procedures into understandable diagrams and logical flows.

A good workflow map includes:

- Task sequences

- Responsible actors (people or systems)

- Decision points and branches

- Data inputs and outputs

- Start and end conditions

By mapping workflows, companies create a clear and actionable blueprint that informs ERP configuration and helps drive operational clarity.

Why Business Workflow Matters in ERP Projects

Implementing ERP without clear workflow mapping is like constructing a building without an architectural plan. You might end up with walls and rooms—but no functionality or flow.

Here’s why business workflow mapping is essential:

- ERP Alignment: Ensures the ERP system is set up based on actual operations.

- Process Clarity: Identifies gaps, overlaps, and inefficiencies.

- User Buy-In: Helps staff understand and adopt the system faster.

- Strategic Automation: Enables ERP to automate where it counts.

- Cross-Department Insight: Encourages collaboration across roles and departments.

The Danger of Broken or Unmapped Workflows

Ignoring business workflows during ERP implementation can lead to serious issues:

- Shadow Systems: Teams revert to spreadsheets and emails to fill system gaps.

- Disconnected Departments: Sales, production, and procurement may operate in silos.

- Rework and Delays: Errors and misunderstandings slow down processes.

- Low ROI: You invest in ERP but don’t gain its full potential.

- Operational Chaos: Without process logic, the ERP becomes an expensive data repository, not a true business tool.

Workflow mapping mitigates these risks by putting structure and visibility into every operational layer.

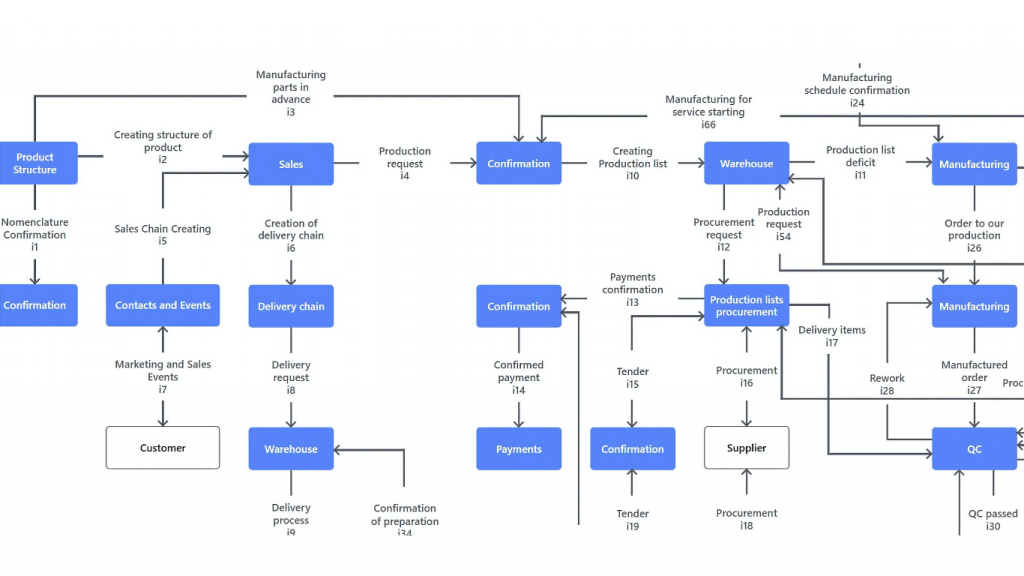

Business Workflow for manufacturing: Real example

To demonstrate how business workflow mapping is applied in real manufacturing environments, this article outlines an example based on a real-world company specializing in the development and production of low-voltage autonomous electric vehicles and smart technologies. The company operates with approximately 120 employees and manufactures solutions for agriculture —integrating advanced radar-based navigation and GNSS-free operation. For more details, check out our guided ERP system with workflow:

Business Flow Diagram Overview

The Business Flow Diagram represents a high-level overview of core manufacturing operations supported by an ERP system. In a modern ERP setup for discrete manufacturing, business logic is designed to follow real-time decision-making, automated task routing, and mandatory confirmations across departments. This comprehensive flow ensures that ERP implementation aligns with how the company truly functions.

Image 1: Business Flow Diagram Overview

Here is how the process unfolds:

- Product Structure Definition

The process begins with defining the product structure (often referred to as the bill of materials or BOM). This includes the specification of all components, subassemblies, and their relationships necessary to manufacture the product. - Production List Creation and Confirmation

Based on the product structure, a production list is generated and confirmed. This step defines what will be produced and serves as the starting point for further planning and execution. - Inventory Check

The warehouse department automatically checks inventory levels in real time. Available quantities are validated, and material availability is assessed to determine procurement and production needs. - Request Generation

Once the inventory check is completed, the system automatically generates two types of requests:- Procurement Requests for items that must be purchased externally.

- Manufacturing Requests for items to be produced internally.

- Manufacturing

The manufacturing team reviews the internal production request and decides whether to produce the components in-house or outsource them. This decision is critical and influences the scheduling and capacity planning modules within the ERP. - Production Request Initiation

For items selected for in-house manufacturing, a production request is created. This includes the specific materials, timelines, workstations, and responsible personnel involved in the task. - Material Collection

Warehouse technicians are instructed to collect the necessary raw materials and components from stock. These are delivered to the production line, ensuring everything required is on hand before manufacturing begins. - Production Execution and Confirmation

Once production is completed, a responsible person in the production department verifies and marks the task as complete in the ERP system. This provides traceability and supports real-time progress tracking. - Quality Control (QC)

Finished items are transferred to the QC department, where they are reviewed for compliance with quality standards. Products that pass are approved; those that fail are either rejected or sent back for correction. - Final Warehouse Allocation

Approved items are returned to the warehouse and allocated to appropriate shelves based on type, destination, or stock rotation logic. These items are now ready for delivery or internal use.

This flow ensures tight integration across departments—linking engineering, warehouse, procurement, production, and quality control in a unified process supported by the ERP system. Each step is connected with clear dependencies, automated triggers, and responsible roles, enabling traceability and operational efficiency from start to finish.

For more details , check out our Binu ERP – basic functionality

Business Process Mapping

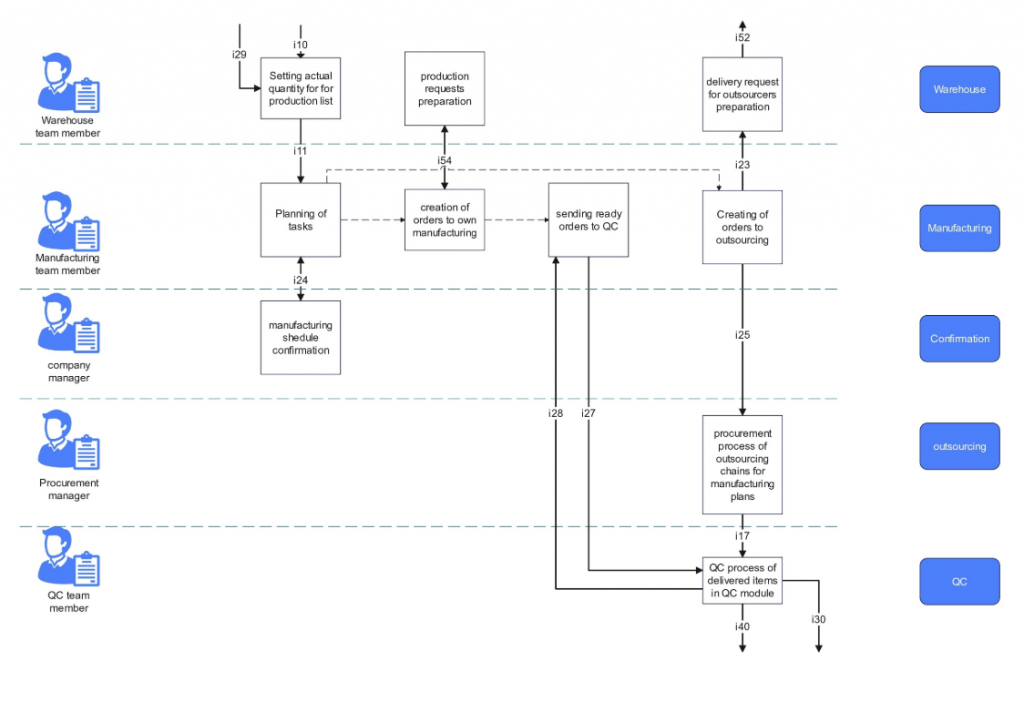

When preparing a business workflow for ERP implementation—especially in complex manufacturing environments—companies must take into account more than just the tasks themselves. Effective workflow mapping hinges on understanding the deeper structure behind each process.

Here are the key elements to define before any ERP configuration:

1. Start and End Points

Identify where each business process begins and ends. In manufacturing, for instance, the process might start with a confirmed product structure and end with a finished product being allocated to the warehouse.

2. Tasks and Activities

Document every major activity in sequence. For the production process, that could include creating a production list, checking inventory, submitting procurement requests, internal or outsourced production, quality control, and final warehousing.

3. Stakeholders

List all actors responsible for tasks—such as warehouse technicians, procurement officers, production managers, and QC inspectors. Knowing who is responsible ensures accountability and clarifies user roles in ERP.

4. Data and Systems

Every task involves data. Document what information is used or generated at each step (e.g., BOM details, inventory levels, supplier lead times), and which ERP modules or systems handle the data.

5. Decision Points

Map out where choices are made. For example, in the production process, a key decision is whether to manufacture in-house or outsource. These forks in the process must be clearly represented to allow for dynamic ERP workflows.

By carefully documenting these elements, manufacturers build a workflow map that serves as the operational backbone of ERP implementation.

Below is a visual representation of the production process mapping based on the real-world manufacturing workflow of the company example described above.

Image 2: Production process mapping

Conclusion: Why Workflow Mapping Is Non-Negotiable in ERP Projects

Business workflow mapping isn’t just a preliminary step—it’s a strategic imperative for ERP success. For manufacturers, where operations are complex and cross-functional, mapping workflows turns abstract processes into tangible, executable structures.

A well-designed workflow:

- Reduces ambiguity across departments

- Aligns ERP configuration with real business needs

- Minimizes risk of project failure

- Boosts automation and visibility

- Increases ROI from ERP investments

With tools like Binu ERP, these workflows aren’t just theoretical—they are operationally embedded, ensuring that every business process is supported, tracked, and continuously improved.

Start with clarity. Map your workflows. Then let ERP do what it does best—drive your manufacturing forward.

Frequently Asked Questions (FAQ)

1. What is ERP business process mapping in manufacturing?

ERP business process mapping in manufacturing is the practice of visually documenting workflows—like inventory checks, production requests, and quality control—so that ERP systems can be tailored to match real operational processes.

2. Why is workflow mapping important before ERP implementation?

Workflow mapping ensures the ERP system is aligned with actual operations. It helps identify inefficiencies, reduces implementation risks, and ensures all departments understand their roles within the new system.

3. What happens if we skip workflow mapping in ERP projects?

Skipping workflow mapping can lead to disconnected systems, manual workarounds (like spreadsheets), process delays, and a poor return on your ERP investment. It often results in user frustration and failed implementations.

4. How does workflow mapping improve cross-departmental collaboration?

By visualizing the entire business flow—from product definition to quality control—departments like warehouse, procurement, and production gain a shared understanding and can work in sync.

5. What are the key components of a workflow map in manufacturing ERP?

Key components include: task sequences, decision points, responsible stakeholders, data flow, ERP module integration, and defined start/end points for each process.

6. Can workflow mapping help with ERP automation?

Yes. Mapping out workflows identifies repetitive tasks and decision points that are ideal for automation—improving efficiency and freeing staff for higher-value activities.

7. How does Binu ERP support workflow-based manufacturing?

Binu ERP uses real-time business flow diagrams and dynamic task routing to embed workflow logic into each step of the manufacturing process, ensuring alignment, traceability, and automation.

8. What’s the difference between a process map and a business flow diagram?

A process map details step-by-step activities within a task, while a business flow diagram provides a high-level overview of how different processes and departments interact through the ERP.

9. How detailed should our workflow mapping be?

It should be as detailed as needed to capture key decision points, task responsibilities, and data flow—especially in areas like inventory checks, production scheduling, and quality control.

10. Who should be involved in the workflow mapping process?

Stakeholders from all relevant departments—production, warehouse, procurement, quality control, and IT—should be involved to ensure the ERP configuration reflects the actual business needs.