Table of Contents

1. Introduction

BOM management with ERP is essential in today’s fast-paced manufacturing environment, enabling better production control, cost efficiency, and supply chain optimization. As products become more complex and global competition increases, companies are turning to ERP systems to master their BOM management workflows.

ERP BOM management systems offer a comprehensive solution by integrating BOM processes with other critical functions such as inventory management, procurement, and production planning. This integration not only enhances operational efficiency but also ensures real-time visibility and control over the manufacturing process.

This article delves into how ERP systems simplify and enhance BOM management, particularly for complex manufacturing operations. We’ll explore the challenges of traditional BOM management, the key features and benefits of ERP-driven BOM systems, the latest trends and studies in the field, and a case study highlighting Binu’s approach to BOM management.

2. Understanding Bill of Materials (BOM) in Manufacturing

A Bill of Materials (BOM) is a comprehensive list detailing all components, assemblies, sub-assemblies, and materials required to manufacture a product. It serves as a blueprint, guiding the production process from inception to completion.

Types of BOMs:

- Engineering BOM (EBOM): Focuses on product design and is typically developed by the engineering department. Manufacturing BOM (MBOM): Tailored for the manufacturing process, detailing all components needed for production.

- Manufacturing BOM (MBOM): Tailored for the manufacturing process, detailing all components needed for production.

- Sales BOM (SBOM): Used in sales processes, outlining products and components as sold.

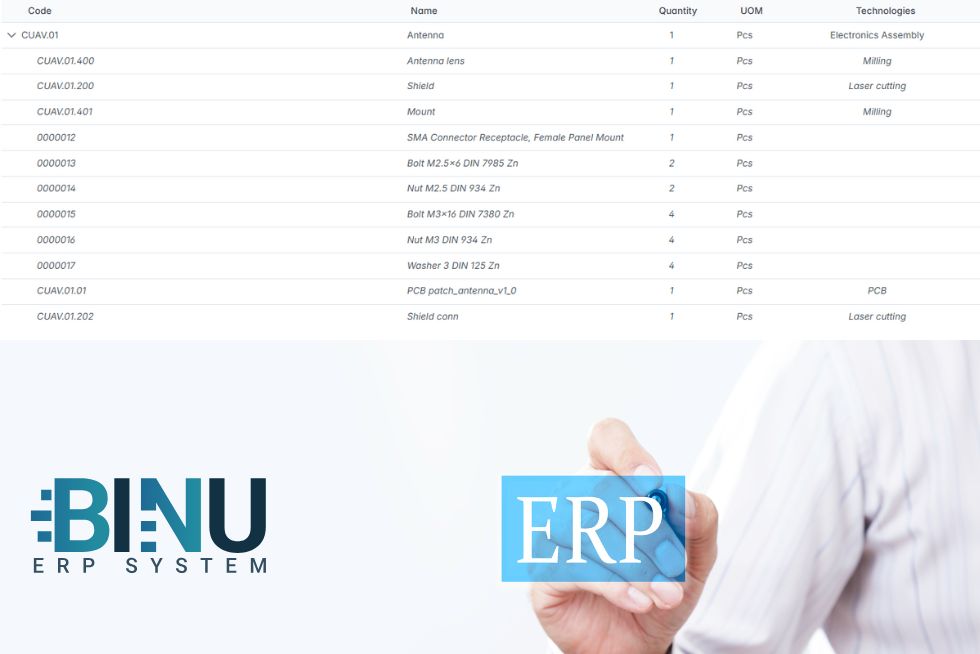

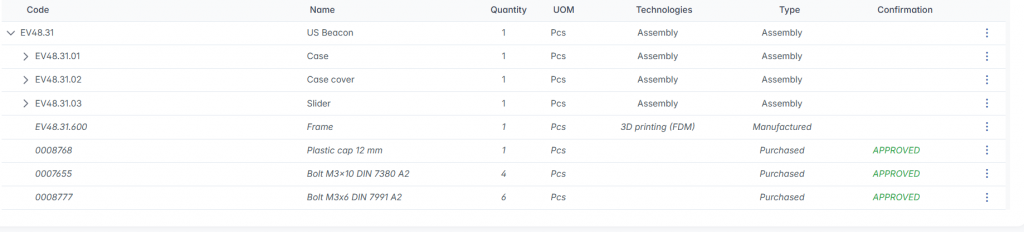

Image: Binu ERP: Product structure

For manufacturers, multi-level BOMs are essential for managing products with nested assemblies and sub-components.

3. What is an ERP System in BOM Management?

ERP (Enterprise Resource Planning) is a system that integrates all business processes into a unified platform. In BOM management, an ERP system:

- Stores BOM data centrally

- Links BOM with procurement, inventory, and production

- Automatically updates changes across modules

- Ensures traceability and revision control

What is an ERP system in a BOM management context? It is the backbone of digital product lifecycle management.

ERP BOM Management System vs Traditional Methods

| Feature | Traditional BOM Management | ERP BOM Management System |

|---|---|---|

| Version Control | Manual, spreadsheets | Automated, centralized |

| Real-Time Updates | Rare | Instant across departments |

| Procurement Integration | Disconnected | Fully integrated |

| Warehouse Coordination | Limited | Streamlined |

| Data Accuracy | Prone to errors | High accuracy |

4. Challenges in Traditional BOM Management

Without ERP integration, BOM management is often manual, error-prone, and disconnected. Relying on spreadsheets or disconnected systems for BOM management presents several challenges. Key challenges include:

- Lack of version control

- Disconnected departments (engineering, production, procurement)

- No real-time updates

- Duplicate data entries

- Inaccurate stock levels

- Delays in production planning

5. BOM Management with ERP: How It Streamlines Manufacturing Operations

Companies struggling with manual BOM processes can benefit significantly from adopting BOM management with ERP solutions like Binu ERP.ERP systems like Binu ERP make BOM management easier by:

- Hierarchical product structures

- Automating BOM (production list) creation and updates

- Procurement request automation

- Integrating with CAD tools like SOLIDWORKS

- Warehouse coordination

- Enabling real-time stock checks

- Quality control workflows

- Supporting production planning and scheduling

6. Benefits of BOM Management with ERP Systems

Manufacturing complex products requires precision. ERP provides:

- Improved Accuracy: Reduces errors associated with manual data entry.

- Enhanced Efficiency: Streamlines production processes, reducing lead times.

- Better Decision-Making: Provides comprehensive data for informed choices.

- Regulatory Compliance: Ensures adherence to industry standards and regulations.

- Scalability: Adapts to growing business needs and complexities

With an ERP BOM management system, companies can automate complex structures and improve traceability.

Example: A car manufacturer managing thousands of components and sub-assemblies with different vendors can streamline operations through ERP.

7. Latest Trends and Studies in BOM Management

Recent studies highlight the evolving landscape of BOM management:

- Integration with CAD Tools: Modern ERP systems now offer seamless integration with CAD software, enhancing design accuracy and reducing time-to-market .

- Cloud-Based Solutions: The shift towards cloud ERP systems offers scalability and remote accessibility, crucial in today’s globalized manufacturing environment .

- AI and Automation: Incorporating AI facilitates predictive analytics, aiding in demand forecasting and inventory management .

8. Case Study: Binu’s Approach to BOM Management

Binu ERP is a comprehensive platform built specifically for manufacturers. Its BOM management features include:

- Multi-level product structures

- Integration with SOLIDWORKS

- Automated production list generation

- Warehouse and locator-based inventory coordination

- Procurement chain automation

- Real-time production status tracking

- Enabling real-time stock checks

- Quality control workflows

- Supporting production planning and scheduling

Explore more at:

Final Thoughts

To remain competitive in modern manufacturing, mastering BOM management with ERP is no longer optional—it’s a necessity. A well-integrated ERP BOM management system helps reduce errors, speed up production, and give you total control over your operations.

With ERP, BOM management becomes a seamless, error-free process tied to every other aspect of your business. Binu ERP is a perfect example of how powerful and customizable such a system can be.

Frequently Asked Questions (FAQ)

1. What is a Bill of Materials (BOM) in manufacturing?

A BOM is a detailed list of all components, raw materials, assemblies, and sub-assemblies required to manufacture a product. It acts as a blueprint for the entire production process.

2. What are the main types of BOM used in manufacturing?

The three primary types are:

- Engineering BOM (EBOM): Based on product design.

- Manufacturing BOM (MBOM): Focused on production needs.

- Sales BOM (SBOM): Used during sales to define sellable products and their components.

3. What role does an ERP system play in BOM management?

An ERP system centralizes BOM data and integrates it with procurement, inventory, and production planning, offering real-time updates, traceability, and version control.

4. How does ERP BOM management differ from traditional methods?

ERP BOM systems offer automation, centralized data, real-time updates, and seamless departmental coordination, unlike manual spreadsheet-based systems which are prone to errors and silos.

5. What are the key challenges of traditional BOM management?

Common issues include lack of version control, disconnected departments, manual errors, duplicate entries, inaccurate stock levels, and delays in production planning.

6. How does an ERP system simplify BOM management processes?

ERP automates BOM creation, integrates with tools like SOLIDWORKS, supports warehouse coordination, triggers procurement actions, and enables real-time stock and production tracking.

7. What are the benefits of using ERP for BOM management?

Key advantages include increased accuracy, operational efficiency, faster decision-making, regulatory compliance, and scalability for growing manufacturing operations.

8. What are the latest trends in ERP-based BOM management?

Emerging trends include CAD integration, cloud-based ERP systems for scalability, and AI-driven automation for predictive inventory and production planning.

9. How does Binu ERP enhance BOM management specifically?

Binu ERP offers features like multi-level BOM structures, automated production lists, CAD integration, warehouse management, real-time production tracking, and quality control workflows.

10. Where can I learn more or see Binu ERP in action?

You can explore Binu’s BOM capabilities and request a live demo at Binu ERP Demo or view their basic functionality overview.