Table of Contents

- Introduction to Article

- What is a Production Planning Tool?

- Manufacturing Planning Methods: Exploring the Key Approaches

- The Role of a Production Planner in Manufacturing

- Production Scheduling Tools for Driving Efficiency in Manufacturing

- Free vs. Paid Production Planning Tools and What to Consider

- Why Choose a Free Production Planning Tool?

- Using Excel for Production Planning and Is it Enough?

- How to Do Production Planning with A Step-by-Step Guide

- What is ERP in Production Planning?

- Benefits of an ERP System in Production Planning

- Key Features of Production Planning Tools

- How Binu ERP Supports Production Planning

- FAQ of Article

Introduction to Article

In the competitive world of manufacturing, effective production planning is crucial. It is the backbone of efficient operations, ensuring that raw materials are used effectively, labor is optimized, and delivery deadlines are met. Without a robust production planning process, companies risk inefficiencies, missed deadlines, and increased operational costs. As more businesses look to streamline their manufacturing processes, the demand for a free production planning template continues to rise.

In this article, we will explore the importance of production planning, how free tools can assist manufacturers, and the role of software solutions, such as Binu ERP System, in transforming the production planning process. We’ll also touch on topics like production scheduling tool, manufacturing planning methods, and ERP systems that enhance production efficiency.

What is a Production Planning Tool?

A production planning tool can be a software application or methodology used by manufacturers to streamline their production processes. These tools help businesses schedule production tasks, allocate resources, and monitor progress in real-time, ensuring that products are manufactured on time, within budget, and to the desired quality standards.

The most effective production planning software integrate various functions of manufacturing, including inventory management, production scheduling, and quality control. Often a part of a bigger system like ERP System or as a stand alone software. By having a clear overview of the production pipeline, manufacturing production planning can optimize their operations and respond quickly to changes in demand. And the better the tool, the better features and hopefully the results.

Manufacturing Planning Methods: Exploring the Key Approaches

Manufacturing planning involves a variety of methods, each designed to meet different operational requirements:

- Just-in-Time (JIT) Planning: Aims to reduce waste by receiving goods only as needed for the production process.

- Material Requirements Planning (MRP): Focuses on planning the material needs for production based on forecasts.

- Lean Manufacturing: Seeks to minimize waste and maximize efficiency throughout the production process.

Using a production planning tool tailored to your chosen method ensures smooth transitions between different stages of production and optimizes the overall workflow.

The Role of a Production Planner in Manufacturing

A production planner in manufacturing oversees the coordination of materials, labor, and equipment to ensure that production schedules are followed efficiently. The production planner uses software tools to:

- Schedule tasks

- Monitor production progress

- Anticipate potential delays

- Ensure optimal use of resources

This crucial role ensures that operations remain on track, minimizing downtime and increasing productivity.

Production Scheduling Tools for Driving Efficiency in Manufacturing

A production scheduling tool helps planning production process, allocate resources and time slots for specific production tasks. These tools are indispensable for:

- Managing production timelines

- Reducing downtime

- Improving overall workflow

- Meeting delivery deadlines

In today’s competitive market, businesses cannot afford inefficiencies. That’s why tools like Binu ERP offer integrated production tools to ensure manufacturers can respond quickly to changes and avoid bottlenecks in their production lines.

Free vs. Paid Production Planning Tools and What to Consider

The market offers both free and paid options for production planning tools. While a free production planning tool can provide essential features, it may lack advanced functionalities that paid software solutions offer. Some considerations when choosing between free and paid tools include:

- Scalability: Free tools may not scale as your manufacturing needs grow.

- Customization: Paid solutions often provide more customization options tailored to your specific processes.

- Support and Training: Free tools typically offer limited support, whereas paid tools come with training and the possibility of customer service.

Choosing the right tool depends on your manufacturing size, budget, and long-term goals.

Why Choose a Free Production Planning Tool?

A free production planning template can be an excellent starting point for smaller manufacturers or those on a tight budget. These tools help streamline production processes without the financial commitment of a paid solution. Some benefits of free tools include:

- No upfront costs with simple template or similar

- Easy-to-use that can be collaborative in Google Sheets or Microsoft Excel

- Basic list features that can be a start for small-scale operations

For manufacturers who are just starting or want to experiment with production planning software, a free tool can provide the functionality needed to get organized and improve operational efficiency or try a free demo for a software could be a place to start.

Using Excel for Production Planning and Is it Enough?

Excel (or similar) is often used as a simple production planning tool, particularly for small manufacturers. While it offers flexibility, there are limitations to consider:

- Manual input: Data must be entered manually, increasing the chance of errors.

- Lack of automation: Excel lacks the automation features of specialized software, which can slow down production.

- Limited scalability: As businesses grow, Excel may become cumbersome to manage.

While production planning tools in Excel are helpful for basic tasks, transitioning to a dedicated production planning system or software will streamline the process and improve accuracy.

How to Do Production Planning with A Step-by-Step Guide

Following these steps helps streamline production and timely delivery of products:

- Forecast Demand: Analyze market trends and historical data to estimate future product demand.

- Create a Production Schedule: Break down the production process into manageable tasks and allocate resources accordingly.

- Monitor Inventory: Ensure that the required materials are available when needed to avoid production delays.

- Optimize Labor and Equipment: Schedule labor and machinery to minimize downtime.

- Adjust for Changes: Continuously monitor production and be flexible in adjusting schedules based on unforeseen challenges.

What is ERP in Production Planning?

ERP (Enterprise Resource Planning) integrates all aspects of manufacturing, including production planning. Production planner tools can also be a part of a ERP system like Binu ensures that production schedules, material management, and quality control are all in one place, allowing businesses to have a complete overview of their operations.

Benefits of an ERP System in Production Planning

- Improved Data Accuracy: All production data is stored in one place, reducing errors.

- Real-Time Updates: Changes in production schedules or inventory levels can be updated instantly.

- Cost Savings: Efficient production planning leads to reduced waste and optimized resource allocation.

- Scalability: ERP systems can grow with your business, offering features suited to larger operations and with collaboration in between departments.

Key Features of Production Planning Tools

A premium or robust production planning software should include:

- Production Scheduling: To organize tasks and allocate resources efficiently.

- Inventory Management: To ensure materials are available when needed.

- Demand Forecasting: To predict future demand and plan production accordingly.

- Real-Time Reporting: To provide updates on production progress and identify bottlenecks.

How Binu ERP Supports Production Planning

Binu ERP offers a comprehensive suite of tools for production planning. With its user-friendly interface and advanced features, manufacturers can streamline operations, reduce waste, and ensure timely deliveries. Whether you need scheduling tools, inventory management, or real-time data reporting, Binu ERP covers all the bases to help your business succeed. Read more about all Binu ERP Modules here.

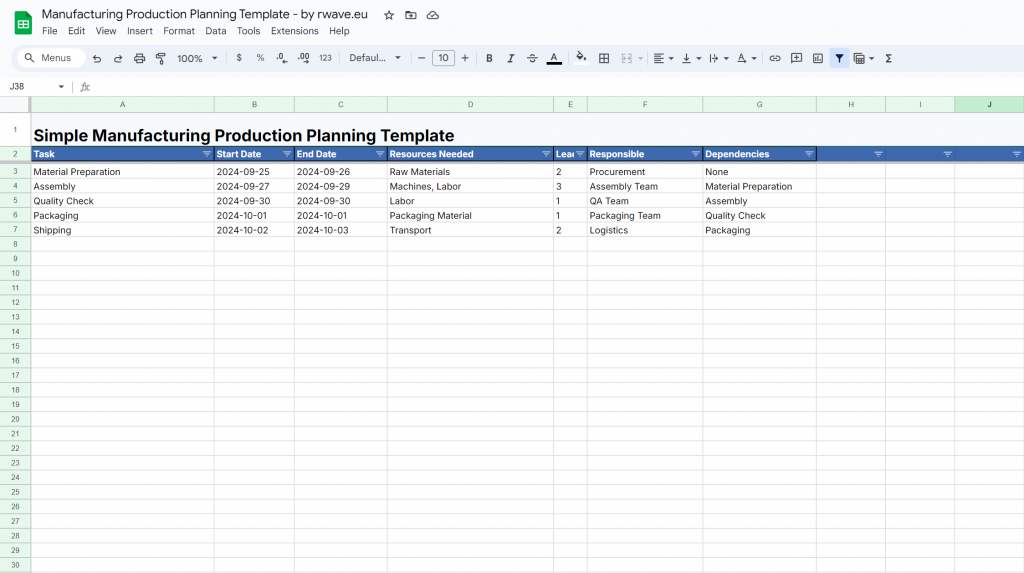

Download Free Production Planning Tool for Manufacturing

We have made one very simple free production list for (discrete) manufacturing that you can modify to your liking or edit to your preferences. Simply opt-in for the document and make your copy or download the document. Modify it for production planning and manufacturing after your needs. The document is made in Google Sheets.

Link to page for downloading free document

FAQ to Article

- What is a production planning tool? A software or methodology used to streamline manufacturing processes.

- Why is production planning important? It helps optimize resources, reduce waste, and meet production deadlines.

- Can I use Excel for production planning? Yes, but it has limitations in automation and scalability.

- What is the best free production planning tool? Tools like Trello or Asana can be used for basic production planning.

- How does an ERP system help with production planning? ERP systems integrate production schedules, material management, and quality control into one platform.

- What is the role of a production planner? A production planner coordinates tasks, resources, and timelines to ensure efficient production.

- What are the key features of production planning software? Production scheduling, inventory management, demand forecasting, and real-time reporting.

- Can small businesses use free production planning tools? Yes, free tools are an excellent option for small manufacturers with limited budgets.

- What is the difference between free and paid production planning tools? Paid tools often offer more advanced features, customization, and scalability.

- How can Binu ERP help with production planning? Binu ERP offers comprehensive tools to streamline production, optimize resources, and improve efficiency.